Software

These drop in serrated grippers can be used to secure base plates and flat bar profiles, as well as angle and other profiles that may have rounded edges which want to push away at the datum line.

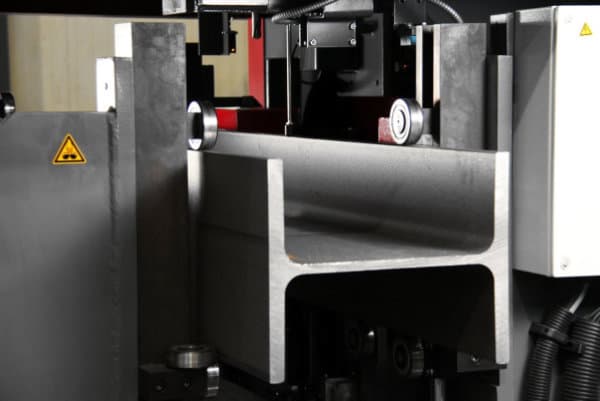

CNC Beam Drill Line is specifically designed for fabricators or general job shops who need to drill holes through steel profiles of all kinds. The following questions can help you decide if this machine is right for your needs.